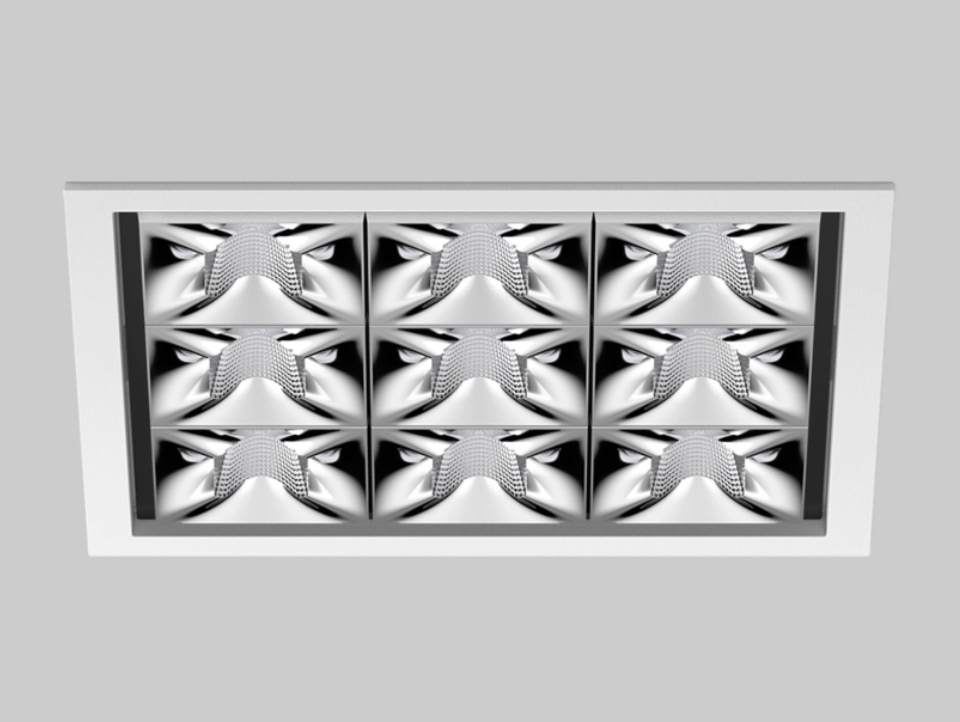

Efficient luminaire design

XAL GmbH

The customer

XAL is an innovative premium manufacturer of luminaires that has been working with architects, designers and planners for over 30 years to develop customised, technologically advanced luminaires. With around 1500 employees at 30 international locations, XAL offers an outstanding level of customer service. The company is an expert in leading lighting solutions and illuminates retail shops, modern office buildings, exclusive hotels, restaurants and private homes worldwide. With organisational efficiency and high in-house production depth, XAL can offer tailor-made solutions that meet the needs of its customers.

The challenge

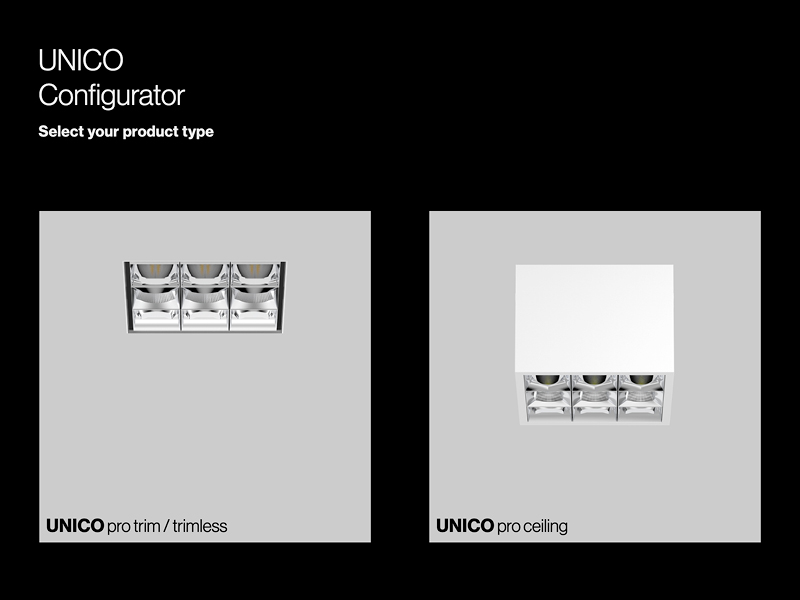

With UNICO, XAL presents a product world full of possibilities. Lighting designers and architects can configure UNICO luminaires according to their own requirements. They have a great deal of design freedom, as over 92.2 quadrillion different variants are possible. Particular emphasis is placed on cost-efficient production in order to optimally realise the wide range of variants.

The solution

Customers can design their customised UNICO luminaire on the XAL website and receive a configuration code for ordering. A clerk checks the configuration light image, creates a sales order or clarifies details directly with the customer. The required data and work plans are automatically transferred to the ERP system and processed. Production of the countless variants is carried out by a robot that automatically generates the corresponding programme based on the UNICO order code. All process steps - from the web configurator to the robot - are seamlessly interlinked.

UNICO Configurator

The result

All processes along the various programmes have been successfully linked together, even though an on-premise AX version is used. The process runs efficiently and requires minimal effort, which enables cost-effective planning and production. In this way, XAL can offer its customers customised luminaires at an attractive price and realise unique lighting projects worldwide.

The feedback

"With the development of UNICO - a downlight with endless design possibilities - the demands on production also increased. We mastered this challenge with automated robot assembly and parts feeding. The linking of order and configuration information from the ERP system with the automated assembly cell enabled us, in collaboration with xalax, to achieve a perfect implementation of ‘Industry 4.0’ - a complete linking of information through all levels of the company."

Mathelitsch Reiner, Manufacturing Engineering Manager, XAL GmbH